Detecting Gasses : Natural Gas (methane), LPG (Liquefied Petroleum Gas)

Sensor Type : Semiconductor (5V±0,1)

Main Body Material : Aluminum

Calibration Time : 1,5 minutes

Reaction Time : <10 seconds

Audible Warnings : Piezoelectric Buzzer

Volume : 85dB

Operating Voltage : 12V DC

Output Signal(Relay Contact : 5A 30VDC NO

Power Consumption : 3W

Operating Area : Industrial Kitchens , Boiler rooms, Gasoline stations etc…

Sensor Protection Class : II G Ex d IIB T6 IP65

Operating Temparature : -10°C….+50°C

Relative Humidity : 0-95%

Estimated Device Life : 5 years

Referans Standarts : TS EN 50194-1, TS EN 60079-0, TS EN 60079-18

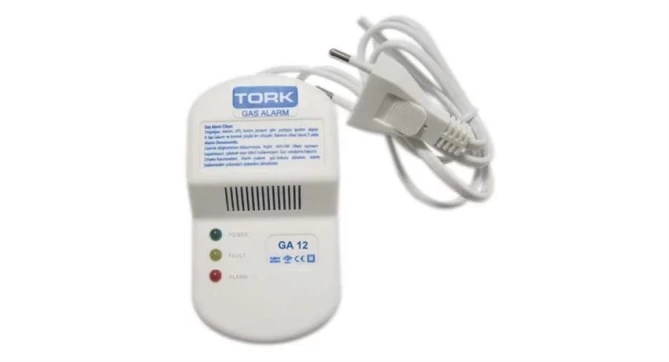

Gas alarm device is a gadget detecting the explosive gasses in environment.Ingredients of the detected gases can be one of these gasses; methane (CH4),propane(C3H8) and butane (C4H10) or mixture of these gasses. Natural gas is methane gas. LPG is made of butane gas,propane gas or mixture of these two gasses. When the gas alarm device is supplied with 230V AC 50/60Hz voltage,green LED lights.

After 1.5 minutes calibrating time (sensor's heating time), device gets active.Before calibrating time is up, don't use any testing gas. After calibrating time , if there is any gas leakage over the limits, the sensor detects the gas in 10 seconds at the latest and gives visual and audible alarm. As long as the gas leakage is upper levels, device goes on to giving alarm. When the leakage level is lower than alarm level, device change to normal condition instinctively , gets ready to detect. If there is no electricity, device does not work. If closing the gas valve or aspirating the gas is wanted when the alarm condition, the output relay of the gas alarm device can be used for it. From the output 230V AC voltage and current lower form 7A can be supplied.

This products consists 3 ( three ) parts.

1. Main body: Sensor is connected to this body with a cable. Visual and audible alarm is in it. This

body is not ex proof and must not be used in explosive area

2.Cable: Cable connects the sensor to the body with a connector. On request it can be produced in

diffrent lengths .It's not exproof in standart production but on request it can be ex proof.

3.Gas sensors with ex proof housing : Sensor is covered with an ex proof housing . This part must be

mounted in explosive area.

Basic Informations

Ex proof gas alarm device, is designed for alerting if there is any leakage of LPG or natural gas on potentially explosive areas like an industrial kitchen or on a boiler room. It's a continuous working and installed on constant place device . Because of its relay output other devices like solenoid valve,aspirator, siren etc. can be controlled.

The minimum concentration of a particular combustible gas or vapor necessary to support its combustion in air is defined as the Lower Explosive Limit (LEL) for that gas. LEL value of natural gas is %5 and LPG's LEL value is %2. Before LEL values not reaching these levels one fifth, gas alarm device detects the leakage and gives alarm.

. Alarm level for natural gas is %0.5 or 5000ppm (parts per million).

. Alarm level for LPG is %0.3 or 3000ppm (parts per million).

Operating Areas

Gas leakage sensor with ex proof housing can be used in kitchens,stokhold and explosive areas like these.

KİŞİSEL VERİLERİN KORUNMASI HAKKINDA BİLGİLENDİRME

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti. ("SMS-TORK") olarak 6698 sayılı Kişisel Verilerin Korunması Kanunu ("KVKK") uyarınca; "Veri Sorumlusu" sıfatıyla, işleme amacı ile bağlantılı, sınırlı ve ölçülü olacak şekilde talep ettiğimiz ve /veya sizlerin bizimle paylaşmış bulunduğunuz kendinize ve/veya 3. kişilere ait kişisel verilerin, yine işlenmelerini gerektiren amaç çerçevesinde; kaydedilecek, depolanacak, muhafaza edilecek, yeniden düzenlenecek, kanunen bu kişisel verileri talep etmeye yetkili olan kurumlar ile paylaşılacak, KVKK'nın öngördüğü hallerde ve koşullarda, yurtiçi veya yurtdışı üçüncü kişilere aktarılabilecek, devredilebilecek, sınıflandınlabilecek ve KVKK’da sayılan sair şekillerde işlenebilecek olduğunu bildiririz.

Kişisel verileriniz, başta kimlik bilgileri olmak üzere, IP, adres, telefon, e- posta adresleri gibi iletişim bilgileri; araç ve plaka bilgileri; aile durum bilgilermiş unvanı, meslek ve işyeri bilgileri; not bilgileri, eğitim düzeyi bilgileri ve fotoğraf, görüntü gibi bilgileri ifade etmektedir.

Kişisel verileriniz, her türlü sözlü, yazılı, elektronik ortamlar, müşteri hizmet merkezimiz, arıza – bakım- onarım servislerimiz, çağrı merkezimiz, internet sayfamız gibi kısmen veya tamamen otomatik olan veya herhangi bir veri sisteminin parçası olmak koşuluyla manuel kanallar aracılığıyla toplanmaktadır. Şirketimiz elde ettiği verileri, kendi bünyesinde işlemenin yanı sıra, yukarıda tanımlanan amaçlar doğrultusunda yurt dışına aktarabilir ve diğer veri korumasına ilişkin mevzuatı farklı olan bölgelerde yer alan kendi işletmelerine, bağlı kuruluşlarına ya da bağlı ortaklıklarına KVK Kanunu’nun 5 ve 6’ ncı maddelerinde belirtilen şart ve amaçlar kapsamında transfer edebilir veya verileri buralarda işleyebilir.

Kişisel verileriniz sözlü, yazılı veya elektronik ortamda; web sitemiz, e-posta veya yazılı başvuru gibi kanallar aracılığıyla toplanabilir. Veriler yasal sürelere tabi olarak kendi veri tabanlarımızda tutulmakta, bulut ortamına aktarılmamaktadır.

Toplanan tüm bilgiler KVKK'nın 11. maddesi gereği bize Veri sahipleri, yukarıda listelenmiş olan haklardan birini kullanmak istedikleri takdirde, Bostancı Yolu Kuru Sokak No:16 Yukarı Dudullu 34776 Ümraniye / İstanbul adresine noter kanalı aracılığıyla başvurarak, Şirketin Bostancı Yolu Kuru Sokak No:16 Yukarı Dudullu 34776 Ümraniye / İstanbul’da bulunan adresine kimlik ibrazı ile bizzat başvuru yaparak veya [email protected] adresine e-posta göndererek kişisel verilerinizin;

Başvurunuzda Veri Sorumlusuna Başvuru Usul ve Esasları Hakkında Tebliğ’in (“Tebliğ”) 5 inci maddesinin 2 inci fıkrasında belirtilen;

a) Ad, soyad ve başvuru yazılı ise imza,

b) Türkiye Cumhuriyeti vatandaşları için T.C. kimlik numarası, yabancılar için uyruğu, pasaport numarası veya varsa kimlik numarası,

c) Tebligata esas yerleşim yeri veya iş yeri adresi,

ç) Varsa bildirime esas elektronik posta adresi, telefon ve faks numarası ve

d) Talep konusunun

Bulunması zorunludur. Bu kapsamdaki başvurularınızı, sitemizde bulunan Veri Sahibi Başvuru Formu’nu kullanarak yapabilirsiniz. Başvurunuz, şirketimizce yapılacak olan kimlik doğrulamasını takiben en kısa sürede ve en geç otuz (30) gün içinde yanıtlanacaktır. Tebliğ’in 7’ nci maddesi uyarınca, başvurunuza yazılı olarak cevap verilmesi durumunda on sayfaya kadar ücret alınmamaktadır. On sayfanın üzerindeki her sayfa için 1 TL işlem ücretinin Tebliğ’e uygun olarak alınacağı hususunu bilgilerinize sunarız.

Talebinizin mahiyetine ve başvuru yönteminize göre Şirket tarafından başvurunun size ait olup olmadığının belirlenmesi ve böylece kişilik haklarınızı koruyabilmek amacıyla kimlik doğrulamaya yönelik ek bilgi (kayıtlı telefonunuza mesaj gönderilmesi, aranmanız gibi) istenebilir. Örneğin Şirkette kayıtlı olan e-posta adresiniz aracılığıyla başvuru yapmanız halinde Şirkette kayıtlı başka bir iletişim yöntemini kullanarak size ulaşabilir ve başvurunun size ait olup olmadığının teyidini isteyebiliriz.

Şirketimiz internet sitesine yapılan ziyaretler esnasında aşağıda bahsi geçen amaçlarla işlenecek veriler toplanırken çerezler (cookies) kullanabilir. Çerez adı verilen teknik iletişim dosyaları, bir internet sitesinin kullanıcının bilgisayarı veya cep telefonu tarayıcısına (browser) gönderdiği küçük metin dosyalarıdır. Tarayıcı aracılığı ile çerezlerin engellenmesi mümkündür. Ziyaretçiler istedikleri her zaman cihazlarındaki program ve/veya işletim sistemi ve/veya internet tarayıcısının ayarlarından çerezleri düzenleyerek kaldırabilirler ve/veya anılan bildirimleri durdurabilirler.

Şirketimiz, kişisel verilere ilişkin politika ve prosedürlerinde mevzuat değişikliklerine uyumu sağlamak üzere değişiklik yapma hakkını saklı tutar.

Saygılarımızla,

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

KİŞİSEL VERİLERİN KORUNMASI HAKKINDA BİLGİLENDİRME

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti. ("SMS-TORK") olarak 6698 sayılı Kişisel Verilerin Korunması Kanunu ("KVKK") uyarınca; "Veri Sorumlusu" sıfatıyla, işleme amacı ile bağlantılı, sınırlı ve ölçülü olacak şekilde talep ettiğimiz ve /veya sizlerin bizimle paylaşmış bulunduğunuz kendinize ve/veya 3. kişilere ait kişisel verilerin, yine işlenmelerini gerektiren amaç çerçevesinde; kaydedilecek, depolanacak, muhafaza edilecek, yeniden düzenlenecek, kanunen bu kişisel verileri talep etmeye yetkili olan kurumlar ile paylaşılacak, KVKK'nın öngördüğü hallerde ve koşullarda, yurtiçi veya yurtdışı üçüncü kişilere aktarılabilecek, devredilebilecek, sınıflandınlabilecek ve KVKK’da sayılan sair şekillerde işlenebilecek olduğunu bildiririz.

Kişisel verileriniz, başta kimlik bilgileri olmak üzere, IP, adres, telefon, e- posta adresleri gibi iletişim bilgileri; araç ve plaka bilgileri; aile durum bilgilermiş unvanı, meslek ve işyeri bilgileri; not bilgileri, eğitim düzeyi bilgileri ve fotoğraf, görüntü gibi bilgileri ifade etmektedir.

Kişisel verileriniz, her türlü sözlü, yazılı, elektronik ortamlar, müşteri hizmet merkezimiz, arıza – bakım- onarım servislerimiz, çağrı merkezimiz, internet sayfamız gibi kısmen veya tamamen otomatik olan veya herhangi bir veri sisteminin parçası olmak koşuluyla manuel kanallar aracılığıyla toplanmaktadır. Şirketimiz elde ettiği verileri, kendi bünyesinde işlemenin yanı sıra, yukarıda tanımlanan amaçlar doğrultusunda yurt dışına aktarabilir ve diğer veri korumasına ilişkin mevzuatı farklı olan bölgelerde yer alan kendi işletmelerine, bağlı kuruluşlarına ya da bağlı ortaklıklarına KVK Kanunu’nun 5 ve 6’ ncı maddelerinde belirtilen şart ve amaçlar kapsamında transfer edebilir veya verileri buralarda işleyebilir.

Kişisel verileriniz sözlü, yazılı veya elektronik ortamda; web sitemiz, e-posta veya yazılı başvuru gibi kanallar aracılığıyla toplanabilir. Veriler yasal sürelere tabi olarak kendi veri tabanlarımızda tutulmakta, bulut ortamına aktarılmamaktadır.

Toplanan tüm bilgiler KVKK'nın 11. maddesi gereği bize Veri sahipleri, yukarıda listelenmiş olan haklardan birini kullanmak istedikleri takdirde, Bostancı Yolu Kuru Sokak No:16 Yukarı Dudullu 34776 Ümraniye / İstanbul adresine noter kanalı aracılığıyla başvurarak, Şirketin Bostancı Yolu Kuru Sokak No:16 Yukarı Dudullu 34776 Ümraniye / İstanbul’da bulunan adresine kimlik ibrazı ile bizzat başvuru yaparak veya [email protected] adresine e-posta göndererek kişisel verilerinizin;

Başvurunuzda Veri Sorumlusuna Başvuru Usul ve Esasları Hakkında Tebliğ’in (“Tebliğ”) 5 inci maddesinin 2 inci fıkrasında belirtilen;

a) Ad, soyad ve başvuru yazılı ise imza,

b) Türkiye Cumhuriyeti vatandaşları için T.C. kimlik numarası, yabancılar için uyruğu, pasaport numarası veya varsa kimlik numarası,

c) Tebligata esas yerleşim yeri veya iş yeri adresi,

ç) Varsa bildirime esas elektronik posta adresi, telefon ve faks numarası ve

d) Talep konusunun

Bulunması zorunludur. Bu kapsamdaki başvurularınızı, sitemizde bulunan Veri Sahibi Başvuru Formu’nu kullanarak yapabilirsiniz. Başvurunuz, şirketimizce yapılacak olan kimlik doğrulamasını takiben en kısa sürede ve en geç otuz (30) gün içinde yanıtlanacaktır. Tebliğ’in 7’ nci maddesi uyarınca, başvurunuza yazılı olarak cevap verilmesi durumunda on sayfaya kadar ücret alınmamaktadır. On sayfanın üzerindeki her sayfa için 1 TL işlem ücretinin Tebliğ’e uygun olarak alınacağı hususunu bilgilerinize sunarız.

Talebinizin mahiyetine ve başvuru yönteminize göre Şirket tarafından başvurunun size ait olup olmadığının belirlenmesi ve böylece kişilik haklarınızı koruyabilmek amacıyla kimlik doğrulamaya yönelik ek bilgi (kayıtlı telefonunuza mesaj gönderilmesi, aranmanız gibi) istenebilir. Örneğin Şirkette kayıtlı olan e-posta adresiniz aracılığıyla başvuru yapmanız halinde Şirkette kayıtlı başka bir iletişim yöntemini kullanarak size ulaşabilir ve başvurunun size ait olup olmadığının teyidini isteyebiliriz.

Şirketimiz internet sitesine yapılan ziyaretler esnasında aşağıda bahsi geçen amaçlarla işlenecek veriler toplanırken çerezler (cookies) kullanabilir. Çerez adı verilen teknik iletişim dosyaları, bir internet sitesinin kullanıcının bilgisayarı veya cep telefonu tarayıcısına (browser) gönderdiği küçük metin dosyalarıdır. Tarayıcı aracılığı ile çerezlerin engellenmesi mümkündür. Ziyaretçiler istedikleri her zaman cihazlarındaki program ve/veya işletim sistemi ve/veya internet tarayıcısının ayarlarından çerezleri düzenleyerek kaldırabilirler ve/veya anılan bildirimleri durdurabilirler.

Şirketimiz, kişisel verilere ilişkin politika ve prosedürlerinde mevzuat değişikliklerine uyumu sağlamak üzere değişiklik yapma hakkını saklı tutar.

Saygılarımızla,

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.