You can find our interview in the December issue of St.Proses below.

With the SIL 3 certificate obtained at the end of an 18-month period, TORK products can now be used in facilities within the scope of seveso. SMS-TORK Sales and Marketing Manager Ömer Kaya, who stated that SIL is a structure that ensures the probability of failure of not only a single product, but also a complete system, said that according to the scenario given by the supervisory institution during the 4-month test phase, the products were kept at temperatures between -40 degrees and +90 degrees. It says it's operated at varying temperatures.

We talked with Ömer Kaya, who stated that they focused their activities on the chemical, petrochemical and paint sectors after obtaining the SIL 3 certificate for pneumatic actuator product groups, about the technical features of the products with SIL 3 certificate and the targets of SMS TORK for the new year.

Can we get to know your system and solutions?

As SMS TORK company, we manufacture pneumatic actuators, solenoid valves, pulse valves, piston valves and electric actuators. Our company, which was established in 1985, has been serving in the field of process automation for 33 years with its own products. We export to 87 countries in the world. Exports constitute 40% of our total turnover. In 2017, we acquired the Varnasan company. With this cooperation, we also entered the production of ball valves. In the teflon seated valve group, which we call soft seat up to DN200, we manufacture valves with stainless steel, carbon steel, cast iron and ductile iron materials. In this way, we offer our customers complete solutions in the field of both actuators and valves.

What are the sectors and projects that you follow recently?

After receiving our SIL 3 certificate for our pneumatic actuators, we focused on the chemical, petrochemical and paint industries. In addition, food, purification, iron and steel, cement, sugar factories are the sectors we work regularly.

What process did you follow for the SIL certificate of your products? What did this provide for you, what do these product groups provide to users in which environments?

We got the SIL 3 certificate at the end of an 18-month process. 4 months of this passed with tests. According to the scenarios given by the supervisory institution, the products worked in the temperature range between -40 degrees and +90 degrees according to the scenario given by the supervisory institution. At the end of these tests, our pneumatic actuators were awarded the SIL3 certificate. In this way, our products have become usable in facilities covered by seveso. Thanks to this document, our customers using our pneumatic actuators can predict their faults with the information they receive from us. SIL is not just a structure that covers a single product. A structure that allows you to get the probability of failure of the complete system. For this reason, you have to declare the possibility of making mistakes in all components with risk. TORK products can now be used in applications that require such safety.

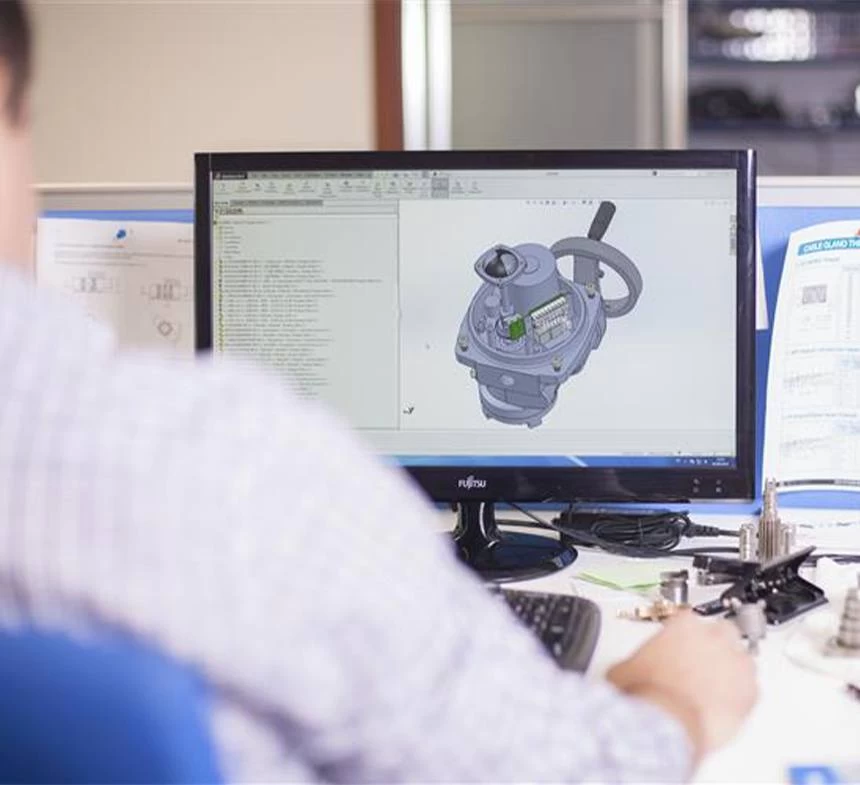

How do you carry out the design studies of your process solutions and projects? Can you share the design process with us?

We are mainly in a position to supply the product that our customers will use in their processes. The most important issue here is to listen well to the other party and to understand the application area and process conditions very well. Foreseeing extreme conditions that may be encountered in the field. Apart from this, since we have been serving in the field of process automation for many years, we have a serious knowledge about material selection according to the fluid. However, when we encounter a new issue, we usually make trials for our customer's process and find the most appropriate result. This process is very important because especially in large investments, since high numbers of actuator valves are used, encountering errors after all products are put into operation brings great problems and costs. Therefore, the design and product selection phase is very important. At this point, we scrutinize too much. In this way, we prevent the problems that may arise during the commissioning of the system to a large extent. Apart from that, of course, the first things learned are standard information such as pressure, temperature, ambient temperature, fluid type.

What are your solutions and services for challenging and dangerous areas?

ATEX certification is available for our solenoid valves, pneumatic and electric actuators and ball valves. In addition, we have ATEX certificate for our devices such as directional valves and switch boxes used with these products. The products that we produce and that have the ATEX certificate can be used in applications up to ZONE 1 class. If we describe it roughly, we can describe it as environments where dangerous gases are present or where there is a danger of being released. This is the safety side of things. Apart from this, there are also issues such as corrosion, high opening and closing process, high or low temperature. These are the main challenges one can face on the field. I would like to mention corrosion as an example. Today, with some coatings on actuators, offshore oil platforms, acid applications, etc., which are highly corrosive environments. We have produced serious solutions to the issues. Our pneumatic actuators can operate up to -50 degrees with the special sealing materials and greases we use. In this regard, we have had serious studies in northern countries and Russia. The biggest problem, especially in pneumatic equipment, is the quality of the air used. Unfortunately, we often encounter the problem of poorly conditioned air in the field. But we overcame this up to a point with a few precautions we took. We attach great importance to the quality of our product processing, the quality of the sealing materials we use, the bedding materials and the surface sensitivity. In the production phase of our products, we have process control, sealing etc. we supply. We subject the parts to input quality control and put them into production if they are produced in accordance with our technical conditions. Then we test all the products we produce before shipment. The most important issue in quality is continuity. We take great care to ensure this.

Are there any companies that you are in contact with (dealer, project) for these sectors? What does this partnership bring you?

We are a company that sells both with our dealers and directly. Both channels have their own advantages and disadvantages. The most important issue for us is to be in constant contact with the customer. We visit more than 4000 customers in a year all over Turkey. In this way, we keep a close eye on the pulse of the market. Project companies (EPC) are an important customer group for us. Because they want to work with brands that they can trust in their projects. Here, product and service quality and customer satisfaction are our priority. Our customers should feel and be sure that we are a company that stands behind our brand. We strive to achieve this. In this way, our products are used in the installation phase in many factories. Apart from this, we have done turnkey automation projects with a project company that we have worked with in this way before.

What are your current success stories in the mining and cement sector? Can we learn the technical details of these projects?

Our most important subject in the cement and mining industry is pulse valves. Pulse valve is an equipment that must be used in filter systems. In recent years, we have made many innovations in our pulse valves. We have increased the intensity produced by the pulse valve, and at the same time, we have increased the strength. This product, which seems to be very simple, requires really good engineering work. Also diaphragm material etc. beyond you. It also requires your sub-suppliers to serve you at a high and standardized quality. All these efforts bore fruit. A high performance product has emerged.

What are the challenges of working in the mining industry? What kind of challenges do you face in projects?

Environmental conditions can be very challenging in the mine. If it is an open area, exposure of the equipment to outdoor conditions seriously affects the life of the product. Your product may be constantly exposed to sun, rain, snow, and dust. Apart from that, if you are going to work underground, standards are very important at this point. In particular, it is necessary to have standards and quality certificates for materials that can create sparks. In addition to this, you should always produce the documents you have with the same quality. This requires serious discipline and follow-up.

At what stage is your current investment? Has production started in your new factory? Can we get to know the technical features of your new facility, production lines and technology investments?

With luck, we aim to move by mid-2019. We are working to ensure that the production process has a lean production logic. We formed a team for this and started to receive consultancy on this issue. We made the transition to the ERP system in the mid-2000s, but we need to go a long way in this regard. We have thrown away a few systems with trials and studies. We have been using IFS since 2012. Realizing ERP requires serious effort. We are working to ensure that every process of our new factory can be traced in a digital environment.

Finally, what would you like to add? (Your agenda, sector-specific project investment and structuring, new brand and product plans, new project topics…etc.)

About a year ago, we finished our first quarter-turn electric actuator. We are currently selling our electric actuators with torque values of 60 and 80 nm. Another 40 nm electric actuator is ending this year. After that, we will continue to manufacture with 150-200 nm and above. In addition, this year we have developed a solenoid valve for cryogenic flows. Our goal in the coming years is to expand our production mostly in the field of electric actuators. In this regard, we aim to be Turkey's brand in the world. Thank you for this interview.